Wij geloven in een toekomst waarbij elektrisch aangedreven schepen een steeds prominentere rol gaan spelen. Door de Hull Vane® kan er worden bijgedragen aan de energietransitie in de maritieme sector. Net …

Lees verder overElektrisch varen? Kom verder met de semi-custom Hull Vane®!

De Hull Vane® zorgt voor een meer comfortabel vaargedrag, doordat het scheepsbewegingen dempt.

De Hull Vane® zorgt voor een meer comfortabel vaargedrag, doordat het scheepsbewegingen dempt.

Met de Hull Vane® maakt uw schip beduidend minder golven en wordt de omgeving minder gestoord.

Met de Hull Vane® maakt uw schip beduidend minder golven en wordt de omgeving minder gestoord.

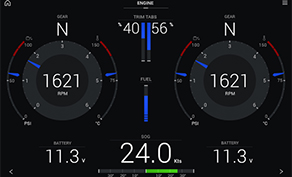

Met de Hull Vane® heeft uw boot een verlaagde weerstand en is een hogere topsnelheid mogelijk met hetzelfde motorvermogen.

Met de Hull Vane® heeft uw boot een verlaagde weerstand en is een hogere topsnelheid mogelijk met hetzelfde motorvermogen.